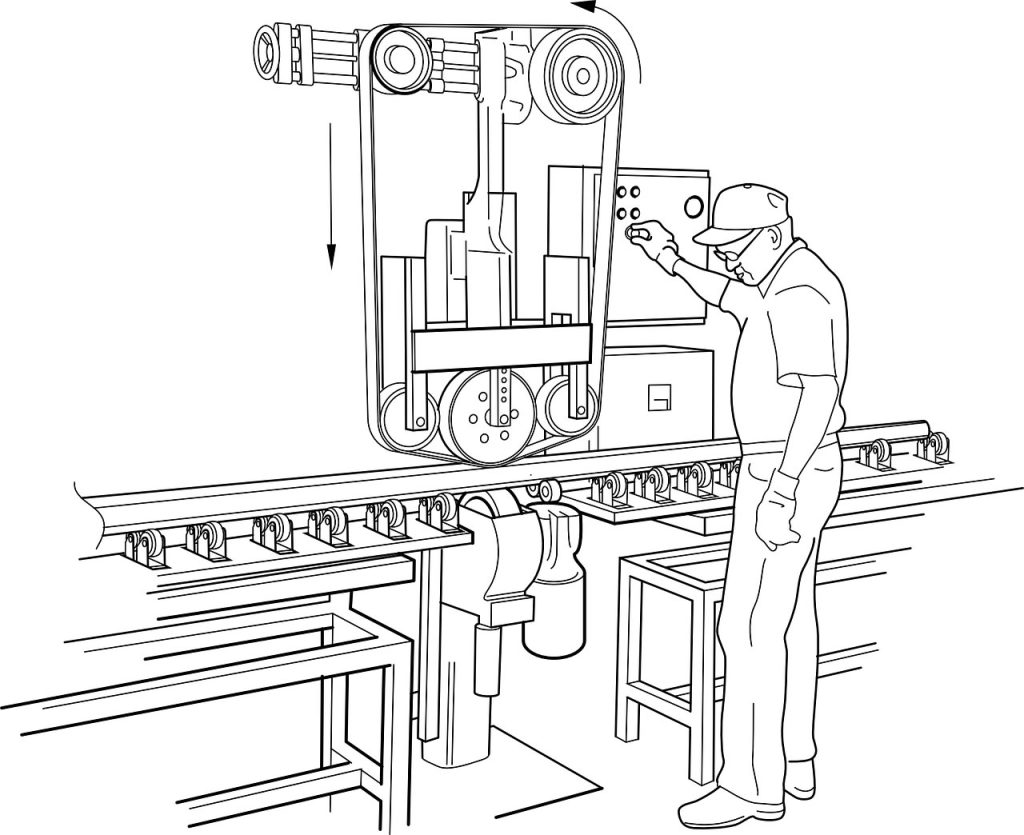

This is One of our Custom Made Machines in previous years.

Automobile Fuel Tank Float Automatic Assembly Line : Optimized Production with Unmatched Quality

Automobile Fuel Tank Float Automatic Assembly Line : Optimized Production with Unmatched Quality

Unmanned Production for Flawless Fuel Tank Floats

The Automobile Fuel Tank Float Automatic Assembly Line is a marvel of modern manufacturing. This system streamlines the production process entirely without manual intervention, leading to several key advantages:

- Unmatched Consistency: Automation ensures every float undergoes identical processes, resulting in consistent quality across the entire production run.

- Enhanced Efficiency: Automatic feeding, welding, and sealing significantly increase production speed compared to manual methods.

- Superior Leak Detection: The integrated positive pressure air leak detection system meticulously identifies any imperfections, guaranteeing only flawless floats move forward.

- Reduced Waste: Automatic sorting eliminates faulty products (NG) from the line, minimizing material waste.

Key Stages of the Automated Process:

- Automatic Feeding: Precisely controlled feeding systems deliver components to the assembly line for a smooth, continuous flow.

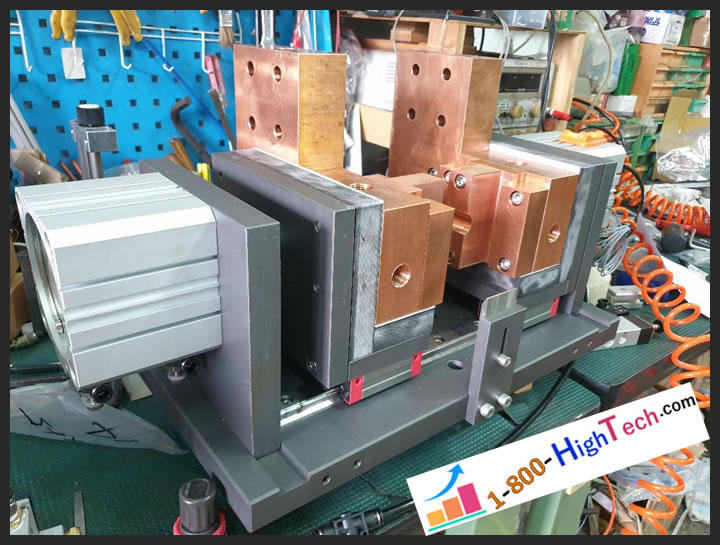

- Automatic Circumferential Welding & Sealing: A computerized system meticulously welds and seals the fuel tank float’s body, creating a robust and leak-proof structure.

- Positive Pressure Air Leak Detection: This advanced technology utilizes pressurized air to pinpoint any imperfections, ensuring only perfect floats proceed.

- Automatic NG/OK Sorting: The system intelligently separates flawless floats (OK) from those with defects (NG).

- OK Product Air Inlet Sealing: The air inlets on the OK floats are securely welded and sealed, finalizing the manufacturing process.

By leveraging automation, this innovative assembly line delivers a high-volume output of exceptional quality fuel tank floats, setting a new standard for efficiency and reliability.

Automation - High Performance - Build-to-Order Machine