Custom Made Machine YP-24H

Shock Absorber SLIM Sheet Automatic Assembly Machine: Revolutionizing Shock Absorber Production

Disclaimer : All Content No Guarantee 100% True and Correct But To Our Best Knowledge

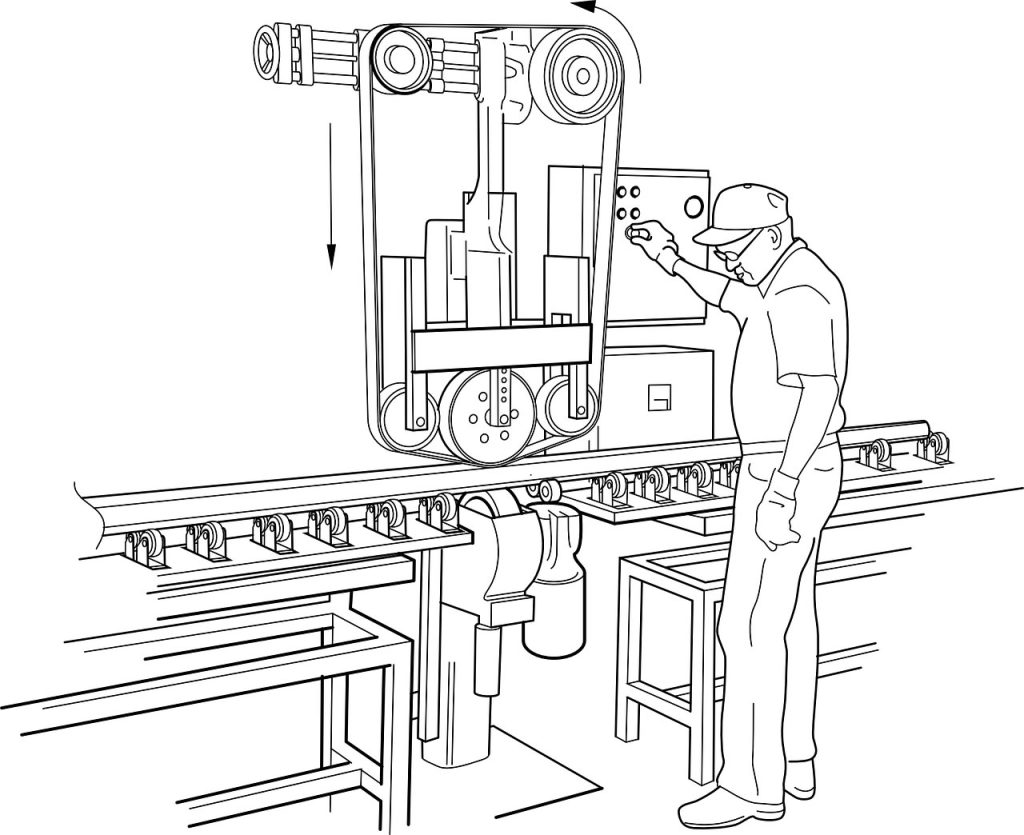

Introducing the Shock Absorber SLIM Sheet Automatic Assembly Machine

An innovative solution that streamlines the assembly process of shock absorbers with SLIM sheets, enhancing precision and productivity.

Addressing Challenges:

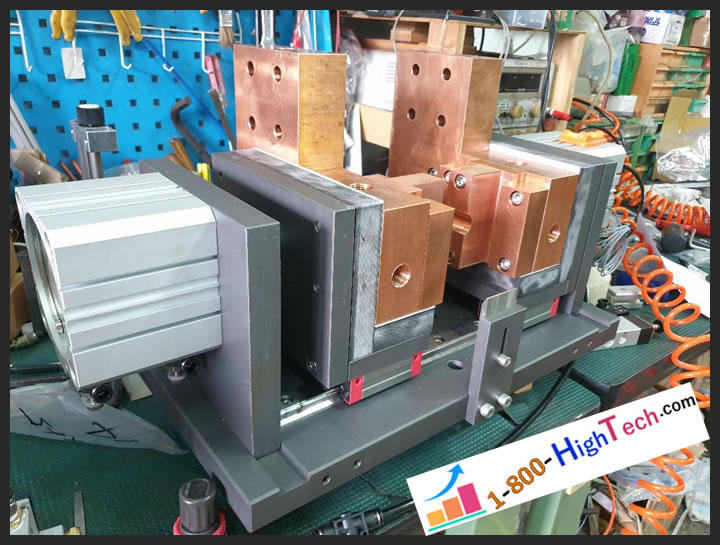

- Variable SLIM Thickness: The machine is designed to handle a wide range of SLIM sheet thicknesses and sizes, seamlessly adapting to different shock absorber requirements.

- Manual Errors: By automating the selection and placement of SLIM sheets, the machine eliminates human error, minimizing the risk of defective products.

Enhanced Production:

- Workstation Organization: Different SLIM sizes are pre-loaded at designated workstations based on operational specifications, ensuring efficient selection.

- Automated Spindle Management: Upon startup, the spindle is installed, and the turntable automatically rotates, stopping at each workstation for precise SLIM sheet placement.

- Automatic Sheet Feeding: The machine autonomously dispenses and drops a single SLIM sheet into the waiting spindle, eliminating manual handling.

- Sequential Filling: This system ensures the SLIM pieces are filled in the correct order, guaranteeing consistent quality.

- Simplified Spindle Removal: Once filled, the spindle can be easily removed for further processing.

Investing in the Future:

- Reduced Defects: Elimination of human error minimizes the production of defective absorbers.

- Increased Efficiency: Automating the process saves significant labor costs and boosts overall production speed.

- Enhanced Quality: Precise control over SLIM sheet placement ensures consistent and high-quality shock absorber assembly.

Investing in the Future:

The Shock Absorber SLIM Sheet Automatic Assembly Machine is a game-changer, offering:

- Improved process control

- Reduced production costs

- Enhanced product quality

- Increased overall productivity

Embrace automation and take your shock absorber production to the next level.

Automation - High Performance - Build-to-Order Machine