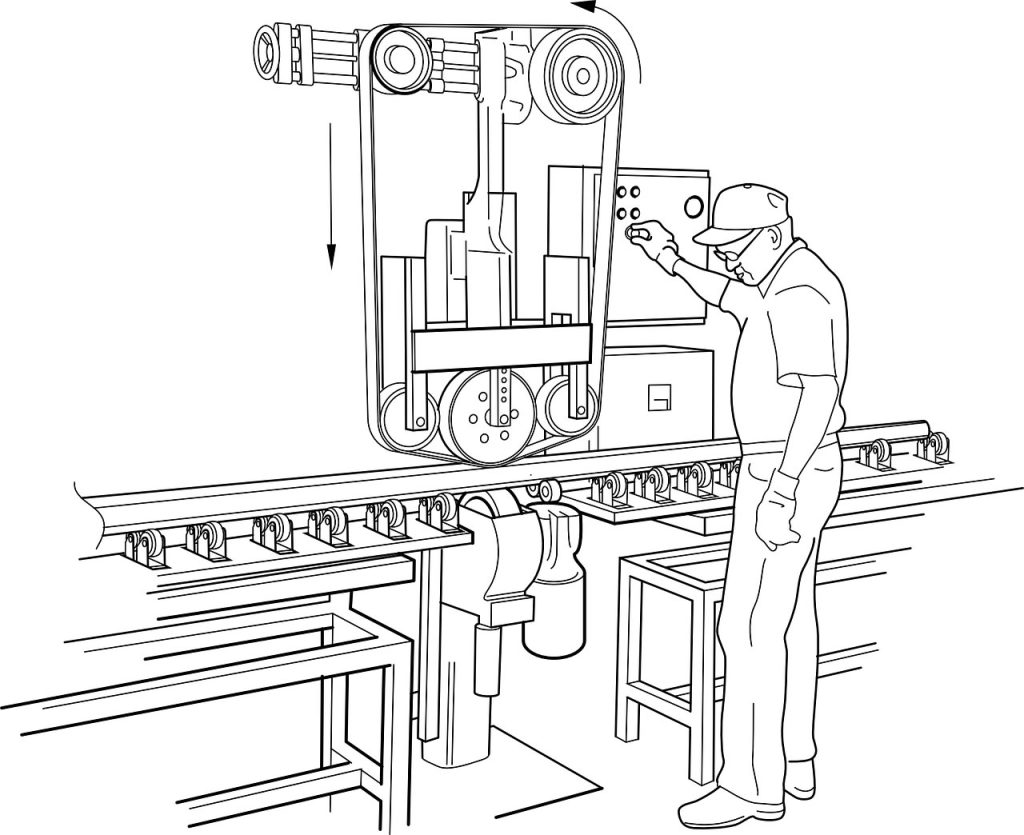

Streamlined Efficiency: Automatic Feeding System Line

Unmatched Speed and Precision in Parts Delivery

The Automatic Feeding System Line is an innovative solution designed to optimize the parts delivery process in your production line. This system leverages automation to achieve:

- Unmanned Operations: Eliminating manual intervention ensures consistent performance and minimizes the risk of human error, ultimately leading to improved production quality.

- Rapid Part Delivery: By utilizing a combination of:

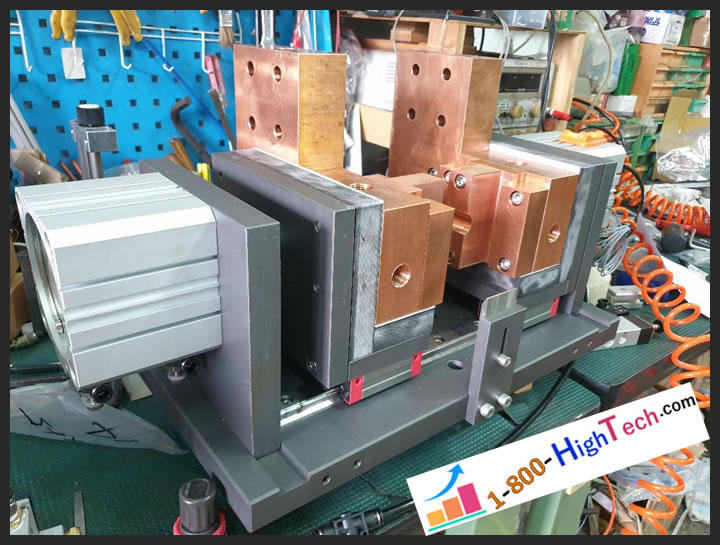

- Disc Vibrating Feeder: This feeder efficiently arranges and vibrates parts for smooth transfer.

- Linear Vibrating Feeder: It further propels the parts towards the designated location.

- Diversion Location: Parts are precisely directed to the correct path.

- Vacuum Suction Cups: Four sets of suction cups meticulously pick up empty parts, ensuring only the desired components reach the production line.

- Robot Arm: The robotic arm seamlessly transfers the workpieces onto the production line.

This system's automation translates to:

- Increased Production Speed: Faster parts delivery keeps your production line running smoothly and efficiently.

- Enhanced Quality Control: Consistent and precise handling minimizes damage and ensures only the correct parts reach the next stage.

The Automatic Feeding System Line is a powerful tool for any production line, offering unmatched speed and precision in parts delivery.

Automation - High Performance - Build-to-Order Machine